Mould Products

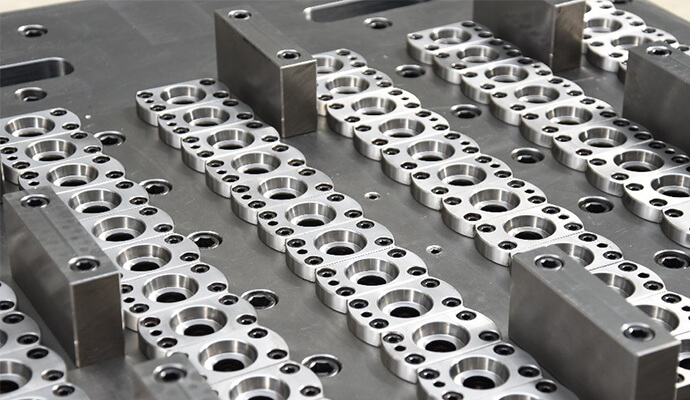

A 15kg pallet has a molding cycle of 69 seconds. This pallet mold utilizes a valve-gate hot runner system and a unique filtration system, enabling recyclable injection molding materials. The mold has passed drop tests, loading tests, and all chemical solution tests required by industry pallet standards.

Including industrial garbage bins, pallet boxes and other industrial molds.Utilizing mold flow analysis technology, we conduct comprehensive evaluations of large-scale industrial mold components, including injection gate positioning, wall thickness optimization of industrial parts, rational flow rate design, as well as impact tests and drop tests.