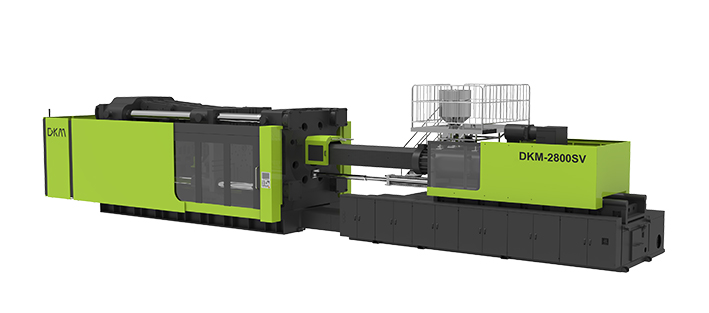

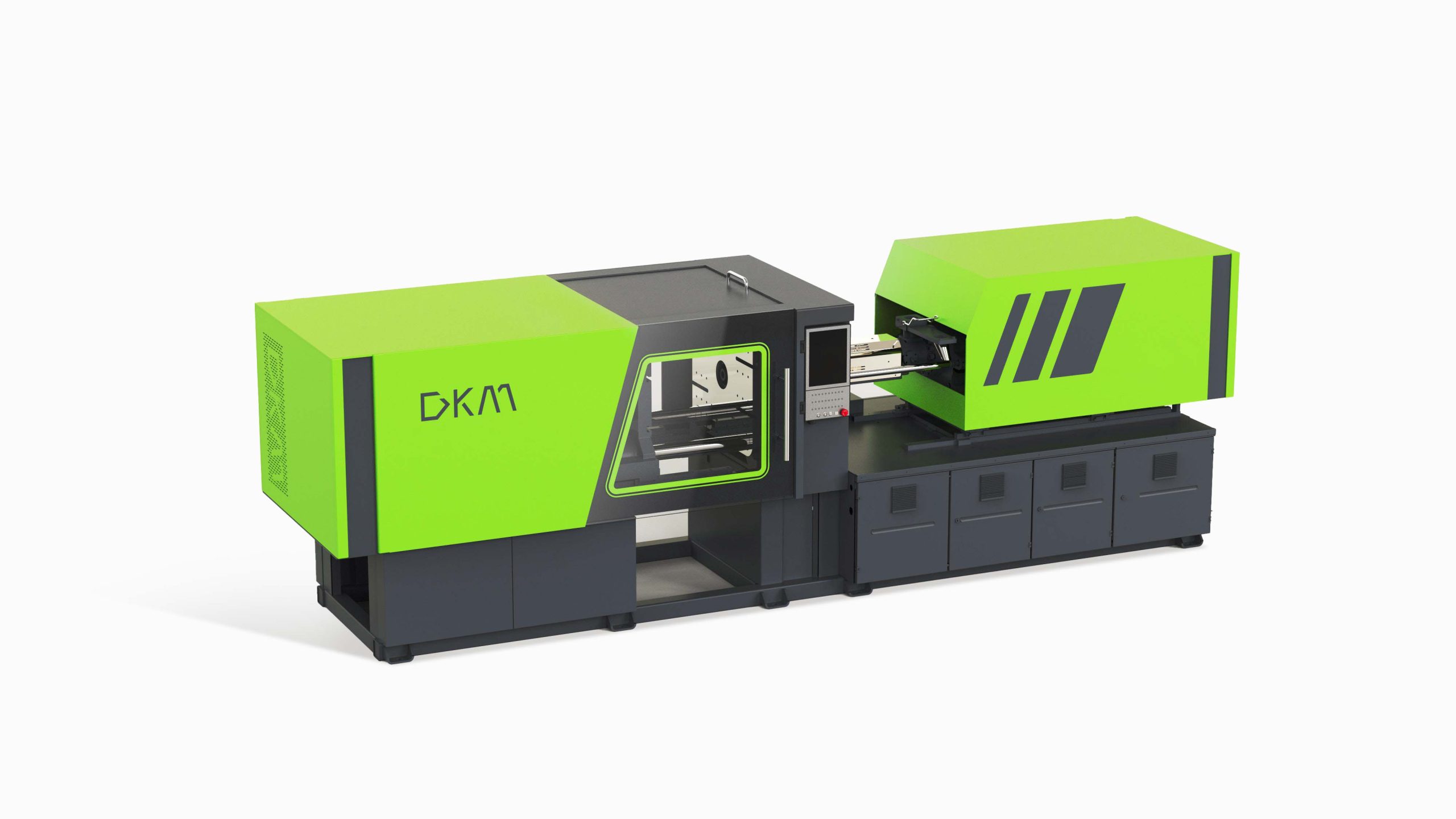

Plastic Injection Molding Machine

WHAT WE OFFER:

These machines deliver stable, efficient, precise, and reliably safe operation.

They meet the diverse needs of the automotive, packaging, logistics, and electronics industries.

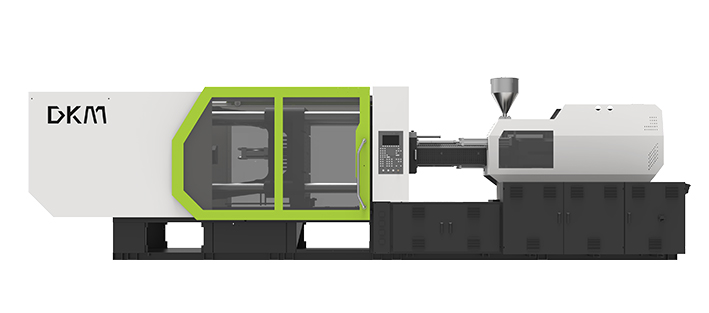

Utilize advanced servo motor technology for precise and efficient operation

High-speed injection enhances productivity

Energy-saving design reduces power consumption

Exceptional precision and repeatability ensure consistent quality

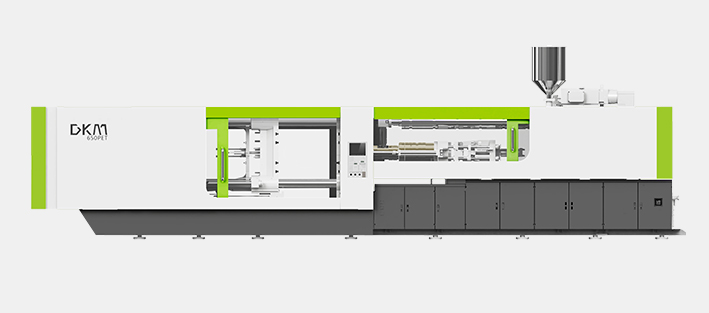

high speed injection molding machines 3 axis linkages realizes material charging, mould opening and ejection at the same time to shorten cycle time and improve production efficiency. With high injection speed and high-response servo-hydraulic system, HH series high speed injection molding machines are suitable for packaging industry especially thin-wall containers.

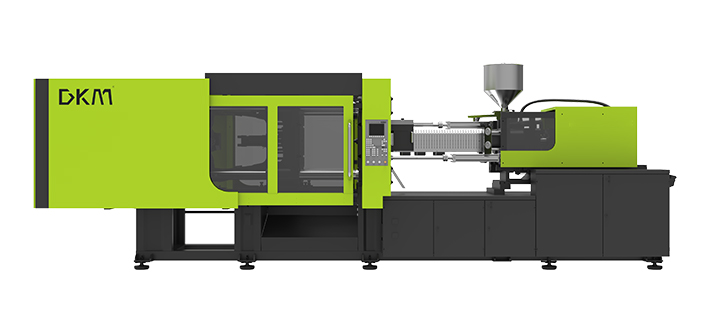

The PET Injection Molding Machine is designed for manufacturing various plastic products using PET as raw material, including PET bottles and PET storage containers.

It features rapid melting, efficient mixing, high-speed injection, and high-precision injection capabilities.

PVC is a versatile material widely used across various industries such as construction, automotive, and packaging.

PVC Injection Molding Machines meticulously developed, delivers exceptional performance, precision, and reliability for injection molding processes.

MX series injection molding machines are designed for making medical equipment and consumables. Considering the strict requirement of cleanness for medical consumables, MX injection molding machines adopt electric ejector cylinder to avoid oil pollution and make clean and precise medical equipment. MX series specialize in the production of a wide range of medical products including but not limited to syringe, test tube, pipette tips, petri dish, etc.

The ideal solution for thin-wall product manufacturing. Utilizing low-inertia, high-precision injection molding technology, it significantly enhances injection speed and accuracy.

These machines offer significant advantages in energy efficiency, production speed, precision, and clean manufacturing processes.

Fast-speed injection molding machines are designed to improve quality and efficiency, with an injection speed of 200 mm/s. fast-speed injection will be a major trend in process reform in the injection molding industry. While ensuring precision molding, the Victor series shortens molding cycles (by 25-50%, depending on mold and product characteristics), significantly improves yield rates, reduces energy consumption, and significantly increases production capacity.